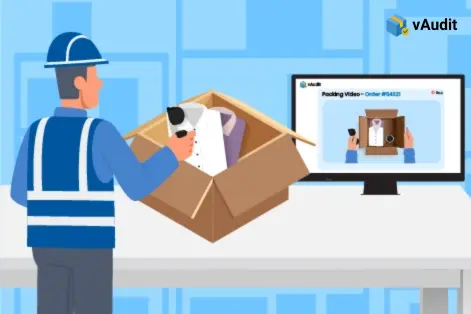

When something’s missing in the box, the packer gets blamed. vAudit records the picker-to-packer handoff and links it to the order ID. Fulfillment leads and warehouse supervisors can now prove what actually arrived at the pack table.

What if you could trace every bin, every time?

With vAudit, you can verify every picker-to-packer transfer in seconds. If an item goes missing, you don’t guess, you go back and watch the moment the bin was dropped.

You’ll know:

Bin Drop Recording

Captures picker placing bin at the pack station

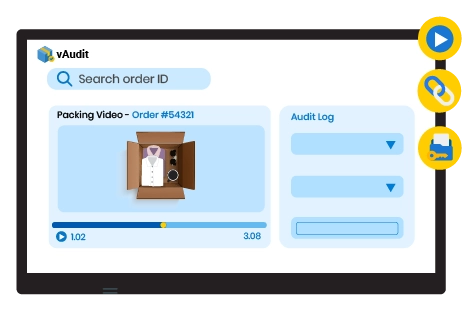

Order ID Linked Video

The picking and packing activity links with the respective order ID

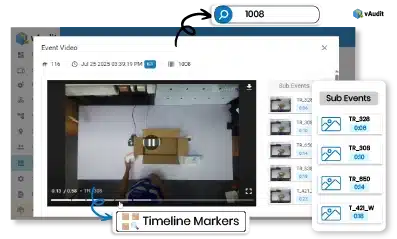

Timestamp Filters

Find footage by time, station, or packer ID

Station Camera Indexing

Sorts video by location and shift

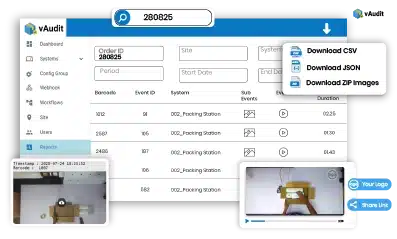

Clip Export + Share

Download or link the exact moment of transfer

vAudit integrates directly into your fulfillment flow, recording picking and packing with timestamped video. Quickly trace errors and confirm handoffs with total visibility.

Picker starts collecting the SKUs for a partiicular order

The bin drops at the pack station

vAudit records the bin delivery and all the items picked are visible

The entire packing process is recorded and timestamped

If there is any error, QA verifies the picker handoff segment of the clip

Root cause of the fulfillment error is confirmed in seconds

Lost track of where things go wrong? Watch the handoff.

vAudit is designed for teams that need visibility by recording picking and packing handoffs. It’s a powerful fit for high-touch operations but not for every workflow.

Your team will have questions. Good ones. Here’s how real champions handle them with facts, not fiction:

vAudit doesn’t just record video, it protects your teams, data, and reputation. From legal disputes to audit reviews, every clip and action is encrypted, access-controlled, and traceable.

All videos are time-stamped, encrypted, and access-controlled, ensuring audit trail integrity.

Only approved users can view or export packing footage.

QA and Finance get compliant records with playback, notes, and timestamps.

Share footage without exposing the full system

SOC 2 Compliant Infrastructure

Enterprise-grade security protocols, encryption, and compliance built for scale. Trusted by regulated industries and modern 3PLs.

This isn’t passive surveillance. It’s purpose-built proof.

Get value from vAudit in just 30 days. Start recording picking and packing, review real handoffs, and resolve root causes without changing your entire workflow.

Every missed item, every re-pick, and every escalation starts with a handoff. Let’s fix it.

Not every fulfillment challenge is about refunds. Discover how vAudit fits across QA, compliance, CX, and escalations. Starting From Day 1.