Regional fulfillment teams gain a clear, consistent view of operations across sites by adding video recording at every pack station. It becomes easier to trace errors, review process gaps, and maintain standard workflows at every site.

In regional 3PL networks, each fulfillment site must follow consistent QA practices to avoid errors and escalations. vAudit delivers video-linked oversight by recording packing videos directly over the packstation, giving teams the tools to review footage, resolve issues, and coach with accuracy across all locations.

vAudit is built for regional 3PLs managing complexity across multiple sites and shifts. If your team needs centralized QA visibility, and real-time video context, here’s how to tell if it’s the right tool for your operation.

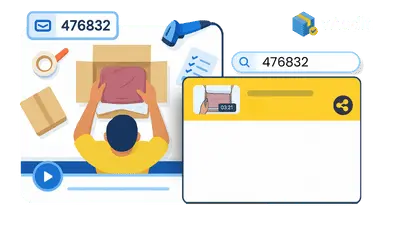

Setting up vAudit for video recording at the pack station takes minutes, not days. Mount the camera, connect it to your existing workflow, and start capturing proof with each scan. There’s no need for major IT effort or process changes. Teams can record, review, and share order-linked footage from day one.

vAudit supports every key role in a regional fulfillment network. By recording packing videos directly over the packstation, teams reduce rework, resolve escalations with proof, and protect brand relationships through consistent QA and site-level visibility.

From customer trust to legal compliance, vAudit is designed to fit securely into the environments that care most about control, privacy, and audit readiness.

You don’t need a full QA overhaul to see value. Start with a guided demo or run a quick pilot by recording videos at packstation. Identify where your network breaks down and resolve real gaps using video proof instead of assumptions or delays.

Not every fulfillment challenge is about refunds. Discover how vAudit fits across QA, compliance, CX, and escalations. Starting From Day 1.