Which vAudit use cases matter most in manufacturing shipping?

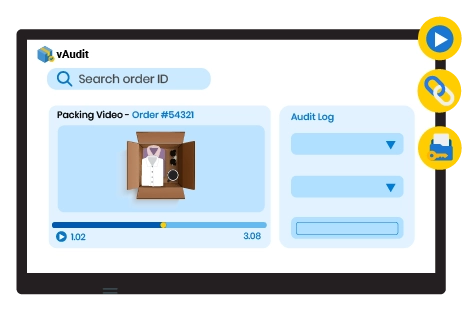

Shipping manufactured goods is judged on accuracy. Part numbers, quantities, labels, and kit completeness. vAudit gives visual proof of outbound shipment to confirm packouts, answer partner questions, and reduce rework without slowing daily output.