ShipStation software is strong for orders and labels. But order verification fails in the handoff between screen and box. The misses are usually small, practical things that happen at the packing station.

As order volume grows, small packing mistakes show up more often. You need accuracy tied to the ShipStation order, not assumptions.

Different brands move through the same packing benches. Each one has its own SKUs, rules, and tolerance for errors.

When order value goes up, tolerance for error drops fast. One missing item can wipe out the margin on several clean shipments. At that point, relying on trust or memory during packing stops working.

Packing issues often show up as refunds, reships, or follow-ups later. The vAudit + ShipStation integration addresses them earlier, at the packing step, where control actually matters.

Wrong item or wrong quantity issues are not edge cases anymore.

You know what the ShipStation order says, but not what actually went into the box.

Some stations pack clean. Others slip, especially when volume changes.

A single error costs more than slowing down for a proper verification step.

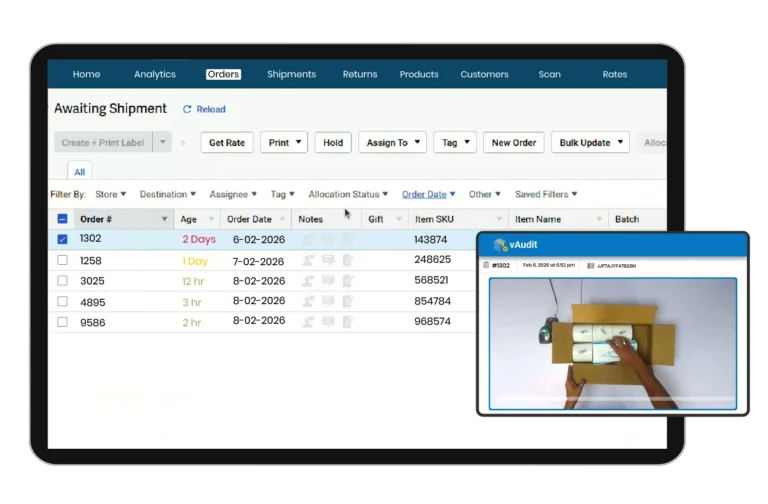

The vAudit + ShipStation integration adds a verification and proof layer at the exact moment orders are packed. It does not change how you create orders or labels. It strengthens what happens between scan and seal.

With the vAudit + ShipStation integration, order verification happens during packing, not after delivery. Teams confirm what goes into the box while the order is still open. Fewer errors leave the warehouse, less rework follows, and disputes are easier to close.

These use cases focus on problems that ShipStation users deal with after orders ship. Situations where the order data looks correct, but the packing step cannot be confirmed. The vAudit + ShipStation integration adds verification and proof at packing, so teams can prevent losses instead of reacting to them later.

The ShipStation order now includes the packing record. Support can confirm what was packed without asking the warehouse to retrace the order.

Shopify stops being order intent only. Your pack process becomes a verified checklist tied to the order, not a manual habit that varies by shift.

High-value orders get a stronger standard without rebuilding your workflow. The Shopify order contains the pack record, the verification trail, and the evidence you need.

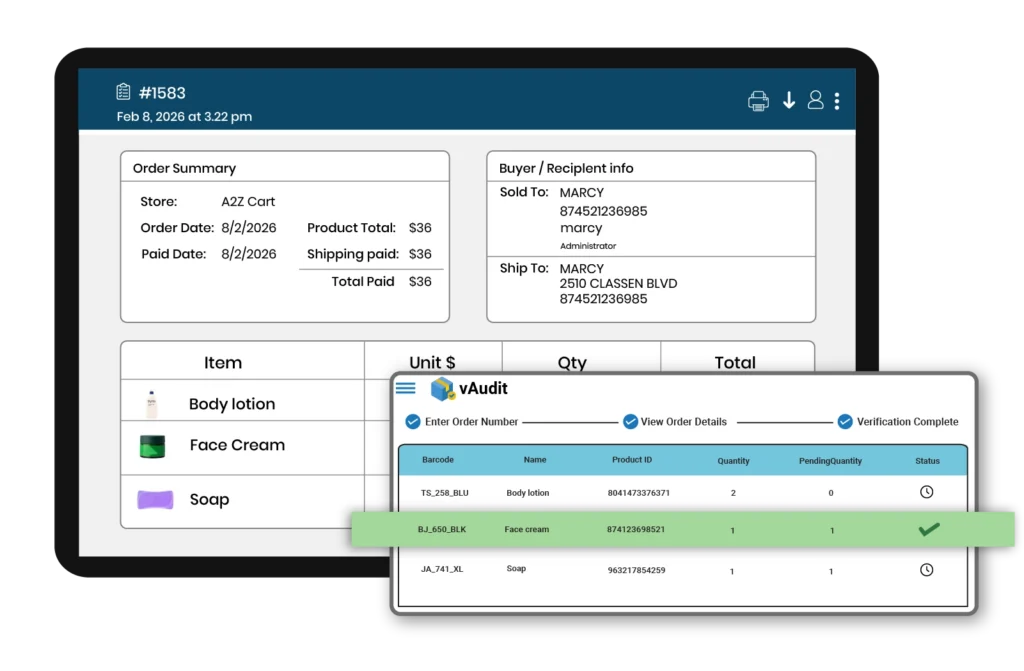

This flow focuses only on verifying that the right items go into the box. ShipStation provides the order details. vAudit enforces item-level checks during packing and stops errors before the shipment moves forward.

vAudit loads the order and displays the packing list at the station.

Each item is scanned and matched against the ShipStation order.

Wrong items, missed scans, or extra quantities are flagged on the spot.

The pack can move forward only after all items are confirmed.

The completed pack record is linked back to the ShipStation order.

The vAudit + ShipStation integration is designed with security and accountability in mind. Access is limited to what the packing workflow requires, activity is recorded for review, and order proof stays connected to the order instead of being copied or shared loosely.

Most teams start small, prove it works on the floor, then expand. The vAudit + ShipStation integration is designed to go live without disrupting daily packing or slowing shipments.

vAudit connects with the systems teams already use to manage order fulfillment. Each integration keeps the original platform as the source of truth while adding order-level packing proof to support daily operations and post-shipment reviews.

See how proof and verification show up inside Shopify orders.